Продукция

تُستخدم محولات سلسلة S الخاصة بنا (مثل طراز S11) قلبًا صفائحيًا متدرجًا ومواد صلب سيليكون موجه الحبيبات، مما يمكن أن يقلل من فقد الحمل بدون حمل بنسبة تصل إلى 30%. يتكيف جهاز تنظيم الجهد بالشريط المغناطيسي المثارة المتكامل (مفتاح تبديل الضبط تحت الحمل) تلقائيًا مع تقلبات الشبكة الكهربائية، مما يضمن استقرار الإخراج. نحن نقدم حلًا شاملاً موثوقًا وعالي الكفاءة لمجال التوزيع الصناعي والعام. نرحب بطلب المواصفات الفنية التفصيلية وكتيبات البيانات.

**مقدمة المنتج**

**سلسلة S**: تشير إلى المحولات التي تستخدم هيكل "قلب ملفوف مجسم" أو "قلب صفائح متدرج". ومع ذلك، في الموديلات القديمة، كان الحرف "S" يمثل مباشرة "ثلاثي الأطوار". في سياق S11، يشير عادةً إلى القلب المصنوع من صفائح السيليكون الموجهة الحبيبات عالية الجودة الملفوفة على البارد وتقنية الصفائح المتدرجة.

**القلب الصفائحي**: يعني أن القلب المغناطيسي للمحول يتكون من صفائح السيليكون المشكّلة بالضغط والمكدسة معًا. هذه التكنولوجيا ناضجة، وهيكلها قوي، وكفاءة إنتاجها عالية.

**تنظيم الجهد بالشريط المغناطيسي المثار**: هذه ميزة أساسية لهذا المنتج. تشير إلى القدرة على ضبط دقيق لجهد الخرج من خلال تغيير عدد اللفات في ملف الجهد العالي للمحول (عادةً عبر مبدل النُقر)، وذلك للتكيف مع تقلبات جهد الشبكة الكهربائية.

**نطاق التطبيق**

يُستخدم هذا المحول على نطاق واسع في أنظمة نقل وتوزيع الطاقة بتردد 50 هرتز وجهد مقنن 10 كيلو فولت أو أقل، وهو مناسب بشكل خاص لـ:

- **تحديث وبناء شبكات الكهرباء في المناطق الحضرية والريفية**: كجهاز أساسي في شبكة التوزيع، لتزويد المجتمعات والقرى بالطاقة.

- **الشركات الصناعية والتعدينية**: لتوفير الطاقة لمعدات الإنتاج في المصانع والمناجم.

- **المباني التجارية والبنية التحتية**: لتزويد المراكز التجارية والمستشفيات والمدارس والمطارات ومحطات القطار بالطاقة.

- **الري الزراعي والاستخدام الكهربائي في الريف**: مناسب للحالات التي يكون فيها تغير الحمل مستقرًا نسبيًا ومتطلبات الضبط الفوري للجهد منخفضة.

- **محطات رفع الجهد لمحطات الطاقة الجديدة** (مثل الطاقة الشمسية وطاقة الرياح) كجزء من محطة محولات مركبة.

**تعليمات الطلب**

【عند تقديم الطلب، يجب تحديد النموذج، السعة المقننة، الجهد المقنن، عدد الأطوار في الجانبين العالي والمنخفض، التردد، رمز مجموعة التوصيل، درجة العزل، الفقد بدون حمل وفقد الحمل، وغيرها من المعلمات】

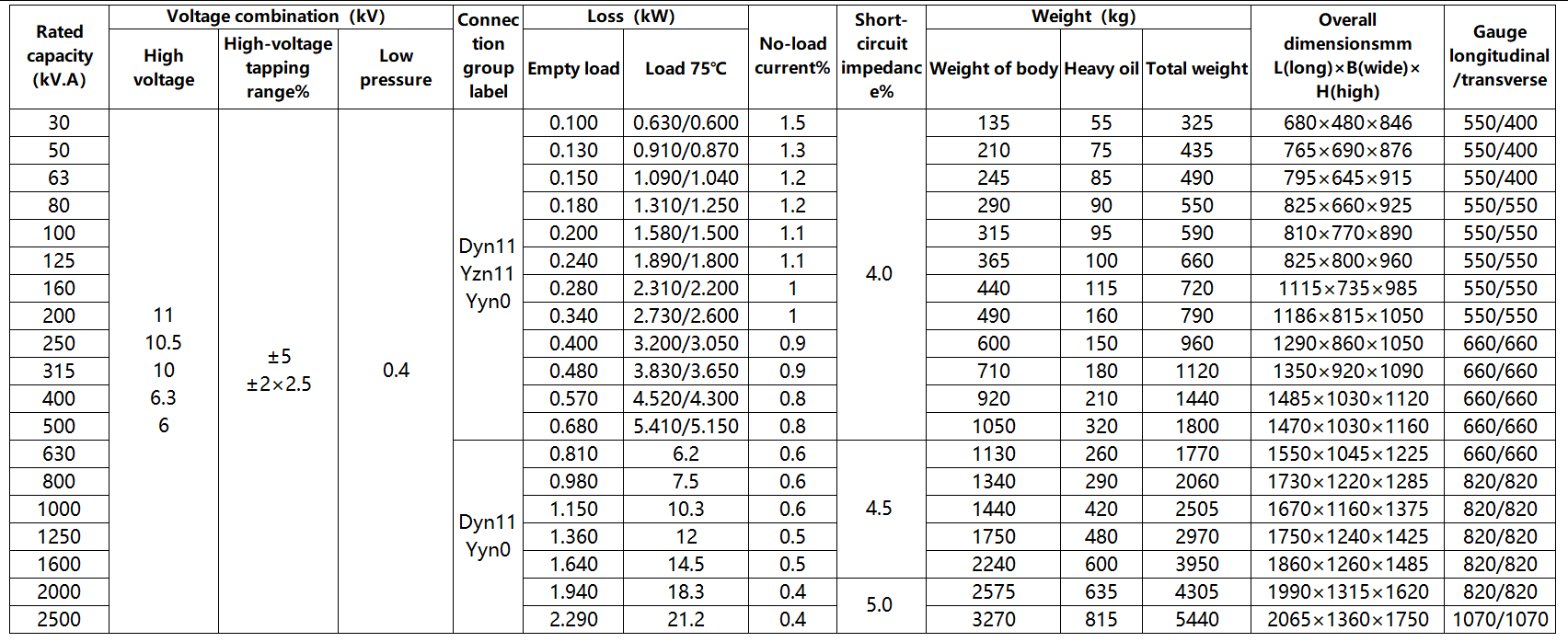

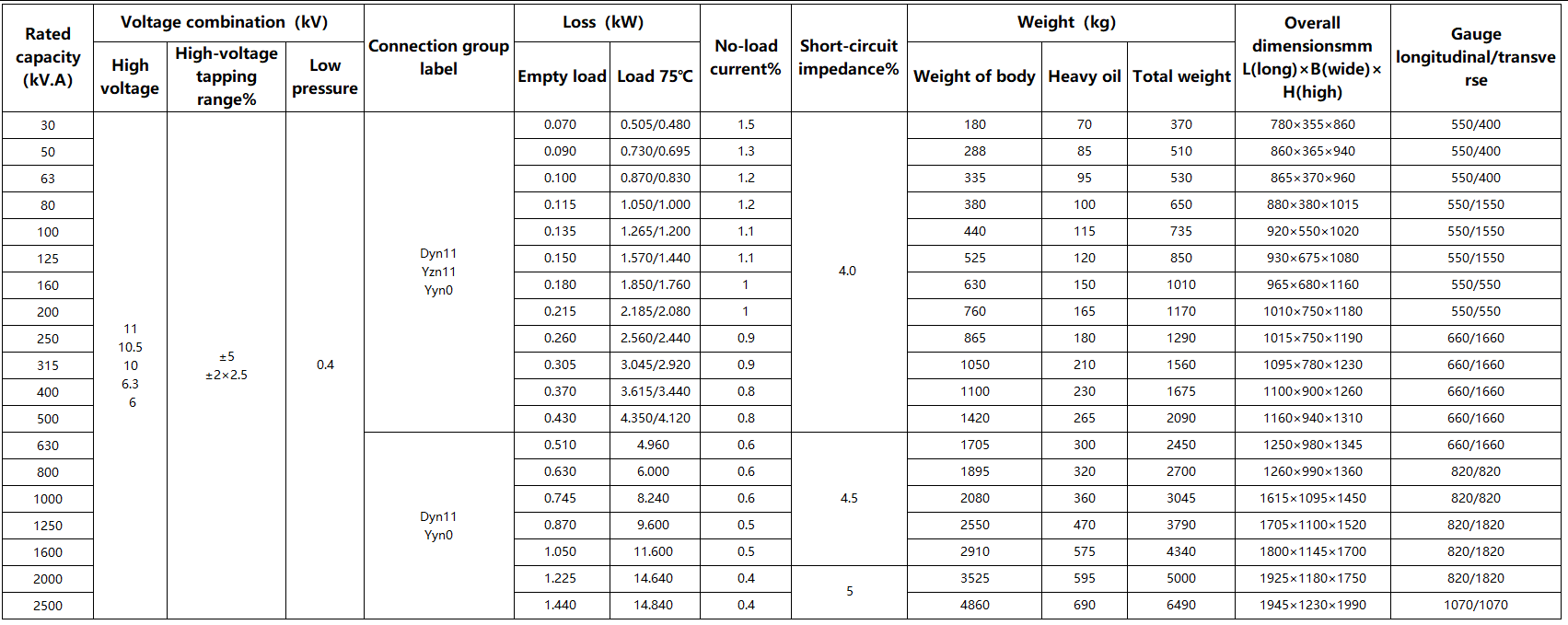

**المعايير الفنية**

المعايير الفنية لمحولات التوزيع سلسلة S11 الغاطسة في الزيت ذات تنظيم الجهد بدون إثارة للمستويات 6 كيلو فولت و 10 كيلو فولت

**ملاحظات هامة**

① بالنسبة للمحولات ثلاثية الطور ذات السعة المقننة 500 كيلو فولت أمبير فأقل، فإن قيم فقد الحمل الواقعة فوق القطر في الجدول تنطبق على مجموعات التوصيل Dyn11 أو Yzn11، بينما تنطبق قيم فقد الحمل الواقعة تحت القطر على مجموعة التوصيل Yyn0.

② عندما يتراوح متوسط معدل حمل المحول السنوي بين 35٪ و 40٪، فإن استخدام معلمات الفقد المذكورة في الجدول يحقق أعلى كفاءة تشغيل.

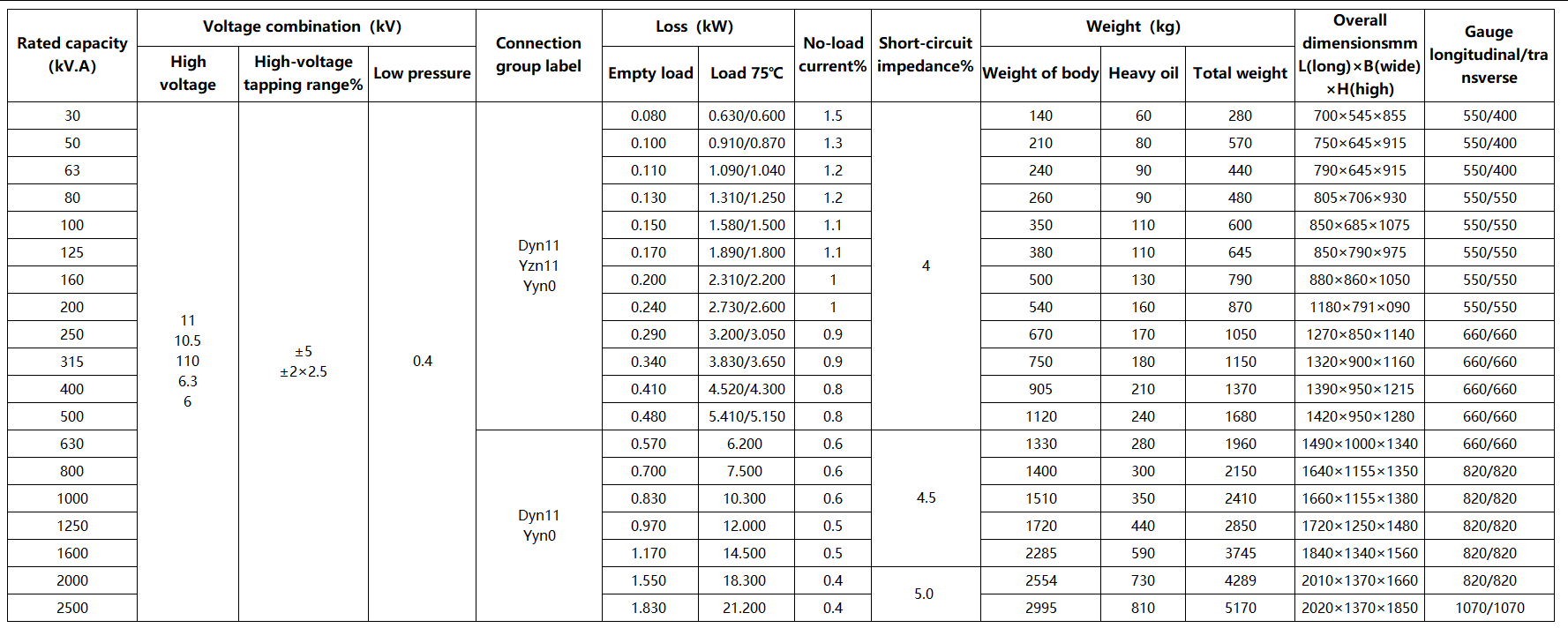

**المواصفات الفنية**

المواصفات الفنية لمحولات التوزيع من السلسلة S13 الغاطسة في الزيت ذات تنظيم الجهد بدون إثارة للمستويات 6 كيلو فولت و 10 كيلو فولت.

**ملاحظات هامة**

① بالنسبة للمحولات ثلاثية الطور ذات السعة المقننة 500 كيلو فولت أمبير فأقل، فإن قيم فقد الحمل فوق القطر في الجدول تنطبق على مجموعات التوصيل Dyn11 أو Yzn11، بينما تنطبق قيم فقد الحمل تحت القطر على مجموعة التوصيل Yyn0.

② عندما يتراوح متوسط معدل حمل المحول السنوي بين 35٪ و40٪، فإن استخدام معايير الفقد المدرجة في الجدول يحقق أعلى كفاءة تشغيل.

**المواصفات الفنية لمحولات التوزيع من السلسلة S20 الغاطسة في الزيت ذات كفاءة الطاقة من المستوى الثاني وتنظيم الجهد بدون إثارة للمستويات 6 كيلو فولت و 10 كيلو فولت**

**ملاحظات هامة**

① بالنسبة للمحولات ثلاثية الطور ذات السعة المقننة 500 كيلو فولت أمبير فأقل، فإن قيم فقد الحمل الواقعة فوق القطر في الجدول تنطبق على مجموعات التوصيل Dyn11 أو Yzn11، بينما تنطبق قيم فقد الحمل الواقعة تحت القطر على مجموعة التوصيل Yyn0.

② عندما يتراوح متوسط معدل حمل المحول السنوي بين 35% و40%، فإن استخدام معايير الفقد المدرجة في الجدول يحقق أعلى كفاءة تشغيل.

③ فقدان الحمل المدرج في الجدول يتوافق مع متطلبات كفاءة الطاقة من المستوى الثالث الواردة في الجدول 1 من المعيار GB20052-2020

Высокоэффективный энергосберегающий трансформатор серии S | Ступенчатый сердечник и технология регулирования напряжения под нагрузкой | Стабильное решение для распределения электроэнергии

Single-Phase Pole-Mounted Transformer - Toroidal Core, High-Efficiency Heat Dissipation, Low-Noise Pole-Mounted Installation Transformer

Производитель эпоксидных литых сухих трансформаторов | Высокоэффективный энергосберегающий огнестойкий взрывозащищенный сухой трансформатор

Однофазный мачтовый трансформатор | Высокоизоляционная защита от утечек | Индивидуальные решения для распределения электроэнергии от Hongye Electric

Выключатель на колонне ZW20-12z

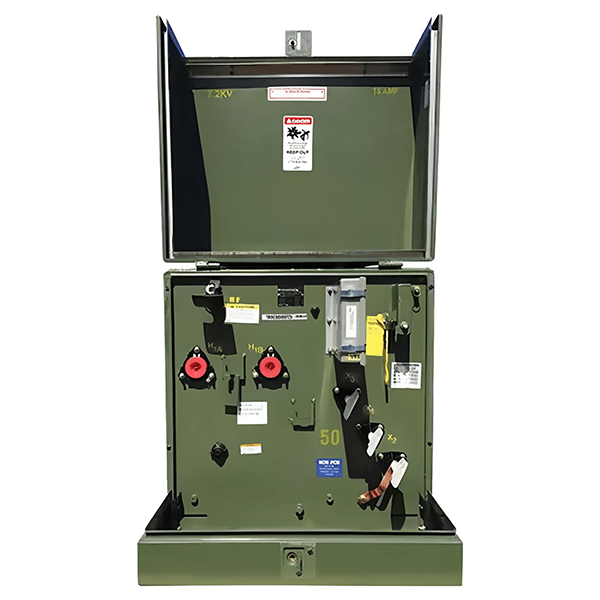

American-Style Three-Phase Pad-Mounted Transformers | Safe & Efficient Grid Solutions

Оставьте свои контактные данные, и мы свяжемся с вами в рабочее время

Главная >

Главная >