Produits

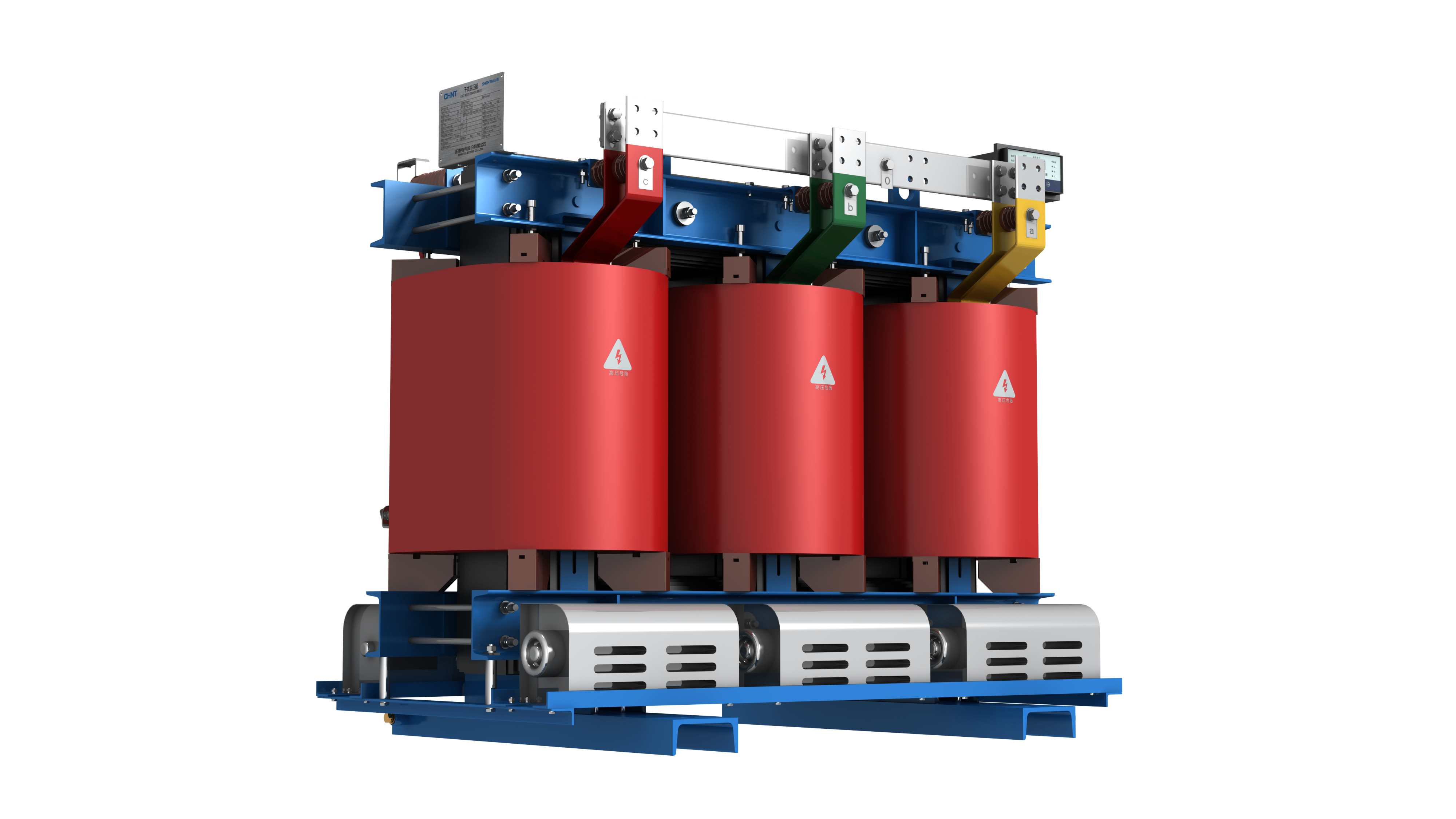

Hongye Electric Group specializes in the production of epoxy resin cast dry-type transformers, utilizing internationally advanced technology to achieve reliability standards at the forefront of the industry. The products are safe, fire-resistant, pollution-free, and can be directly installed in load centers. They are suitable for demanding applications such as high-rise buildings, airports, metro systems, and offshore platforms. Equipped with high energy efficiency, high-quality cores, low-noise operation, and an intelligent temperature control system, they support the enhancement of enterprise power solutions.

Product Introduction

Our

company produces epoxy resin cast dry-type transformers that

incorporate advanced foreign technologies, achieving reliability

indicators aligned with international cutting-edge standards. These

transformers are safe, reliable, fire-resistant, explosion-proof, and

pollution-free, and can be directly installed in load centers. They have

been widely applied in harsh environments and demanding conditions such

as high-rise buildings, commercial complexes, airports, railway

stations, docks, metro systems, factories, underground distribution

rooms, offshore oil drilling platforms, and power plants.

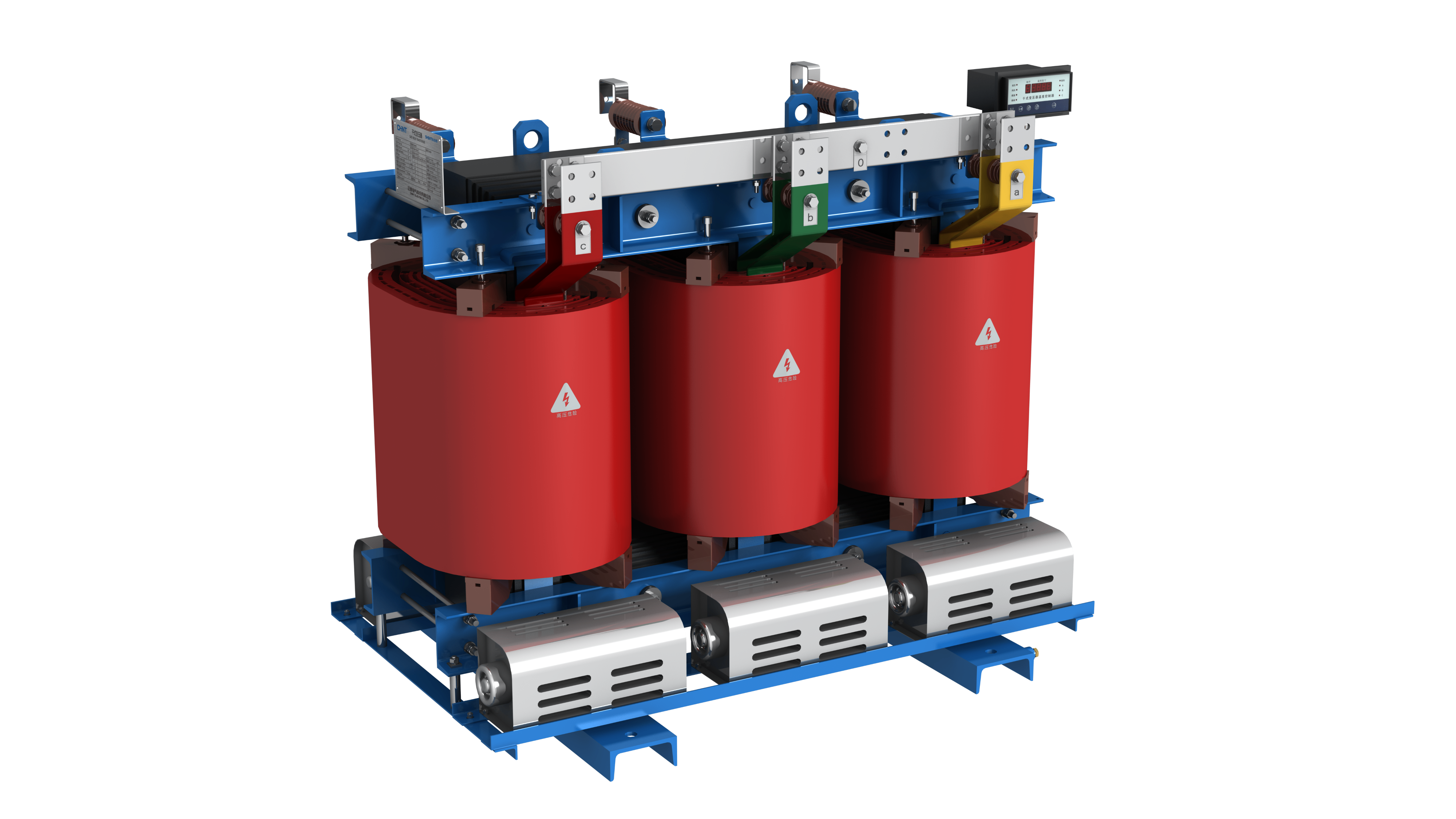

High Efficiency and Energy Saving

Featuring

an enhanced heat dissipation design, the transformers can operate at

150% of the rated load under forced air cooling, ensuring optimal energy

utilization efficiency.

High-Quality Core

Utilizes

imported high-quality cold-rolled silicon steel sheets, with the core

surface encapsulated in epoxy resin. This design effectively reduces

no-load losses and no-load current, significantly improving product

quality.

Low-Noise Operation

Equipped

with cross-flow top-blowing cooling fans, the transformers achieve low

noise levels, high airflow efficiency, and a sleek, aesthetically

pleasing appearance.

Intelligent Temperature Control System

Incorporates an intelligent temperature controller to further enhance operational safety and reliability.

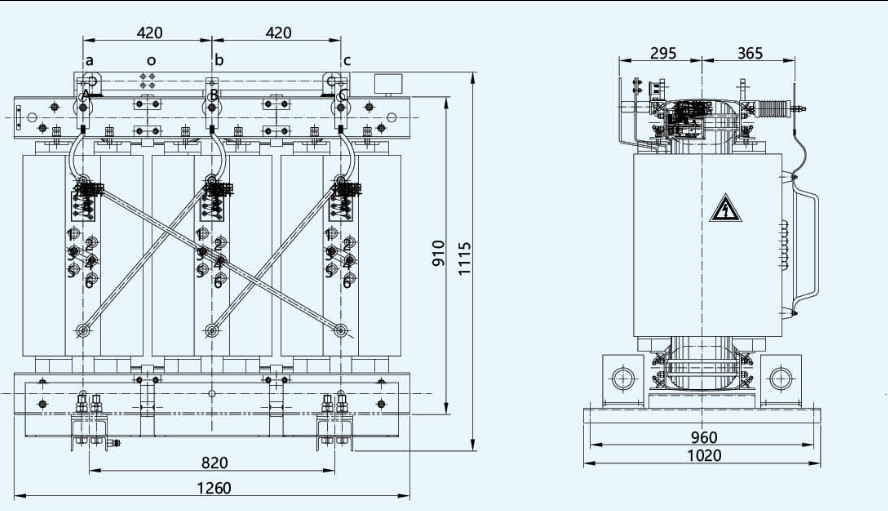

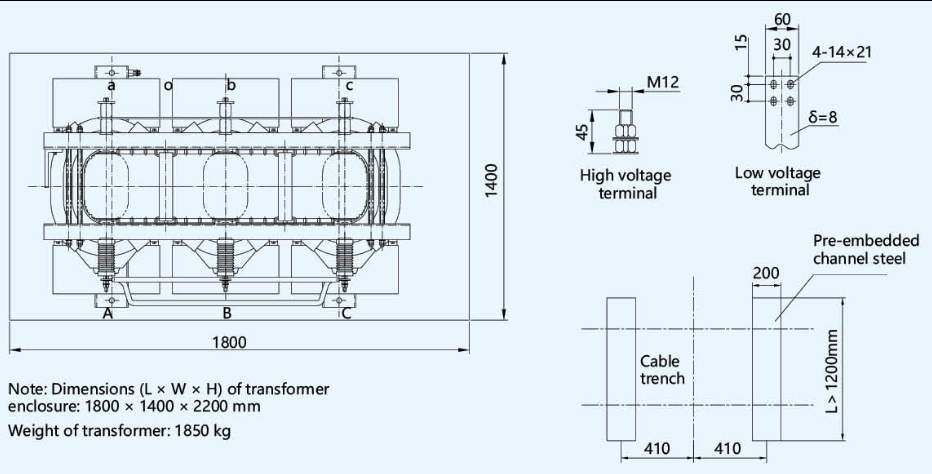

外形尺寸图(毫米)

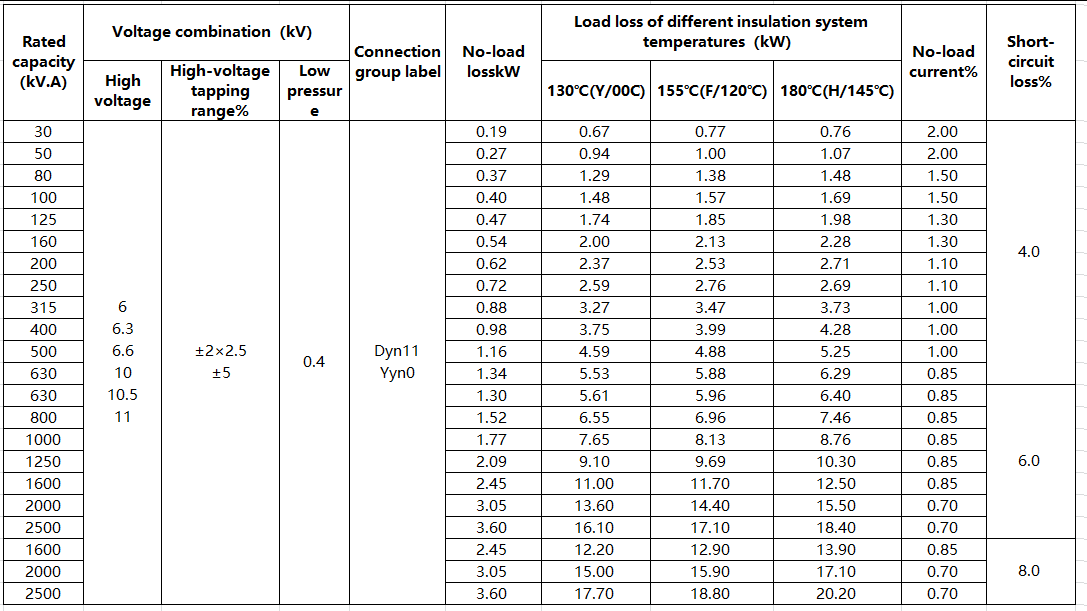

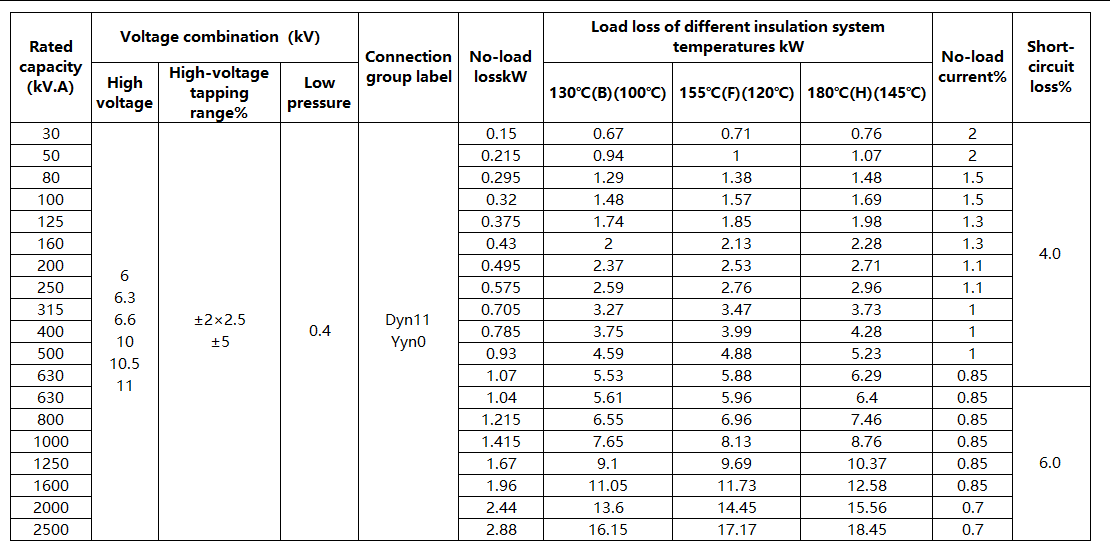

Technical Parameters of SC(B)10 Series 6kV and 10kV Class No-Excitation Voltage Regulation Distribution Electronic Transformers

Note: The load losses listed in the table are based on the reference temperatures (as specified in GB/T1094.11) corresponding to different insulation systems, as indicated in parentheses. For load losses under insulation systems not included in the table, appropriate conversion shall be performed based on their respective reference temperatures, using the data for the +155°C (F) insulation system as a reference.

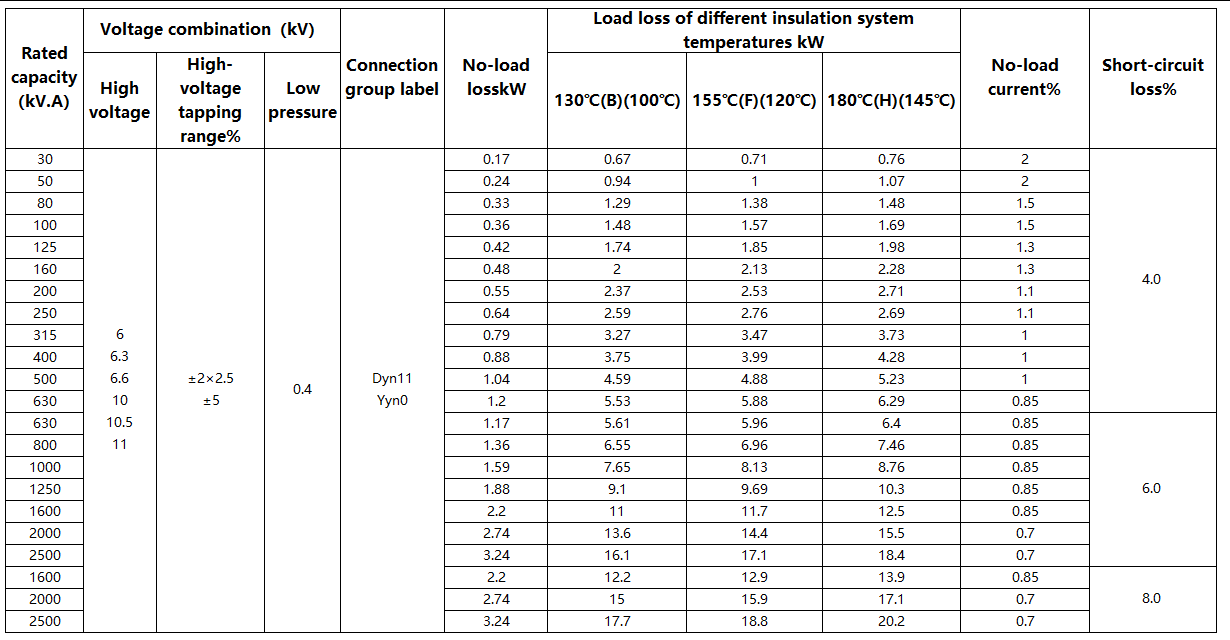

Technical Parameters of SC(B)11 Series 6kV and 10kV Class No-Excitation Voltage Regulation Distribution Dry-Type Transformers

Note: The load losses listed in the table are values under the reference temperatures (specified in GB/T1094.11) for different insulation systems, as indicated in parentheses. For load losses of insulation systems not included in the table, corresponding conversions should be made based on their respective reference temperatures, using the data of the "+155°C (F)" insulation system as a reference.

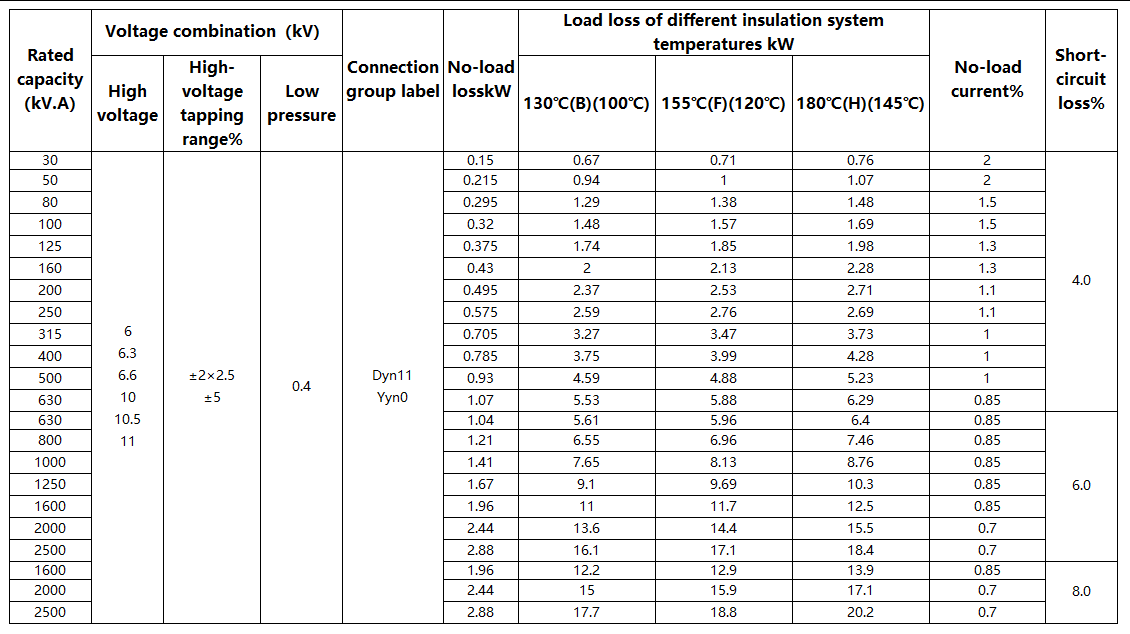

Technical Parameters of SC(B)12 Series 6kV, 10kV Class No-Excitation Voltage Regulation Distribution Dry-Type Transformers

Note: The load losses listed in the table are values at the reference temperatures (specified in GB/T1094.11) for different insulation systems, as indicated in parentheses. For load losses of insulation systems not included in the table, appropriate conversion shall be performed based on their respective reference temperatures, using the data of the "+155°C (F)" insulation system as a reference.

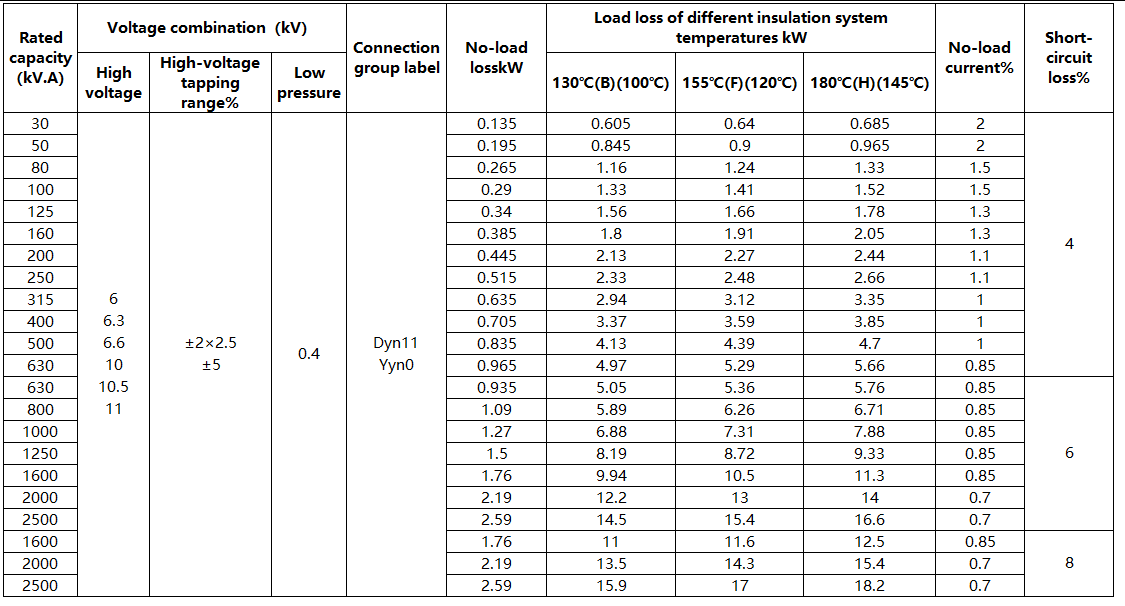

Technical Parameters of SC(B)13 Series 6kV, 10kV Class No-Excitation Voltage Regulation Distribution Dry-Type Transformers

Note: The load losses listed in the table correspond to the reference temperatures (as specified in GB/T1094.11) for different insulation systems, indicated in parentheses. For load losses under insulation systems not included in the table, appropriate conversion shall be performed based on their respective reference temperatures, with reference to the data of the “155°C (F)” insulation system.

Technical Parameters of SC(B)12 Series Grade 3 Energy Efficiency 6kV, 10kV Class No-Excitation Voltage Regulation Distribution Dry-Type Transformers

Note:

①

The load losses listed in the table correspond to the values at the

reference temperatures (as specified in GB/T 1094.11) for different

insulation systems, as indicated in parentheses. For load losses under

insulation systems not included in the table, appropriate conversion

shall be made based on their respective reference temperatures, using

the data of the “155℃(F)” insulation system as a reference.

②

The no-load and load losses listed in the table comply with the Grade 3

energy efficiency requirements specified in Table 2 of GB 20052-2020.

Transformateur haute efficacité série S | Noyau à gradins et technologie de réglage sous charge | Solution de distribution électrique stable

Transformateur monophasé sur colonne

Fabricant de transformateurs secs à coulée de résine époxy | Transformateurs secs haute efficacité, économes en énergie, résistants au feu et anti-explosion

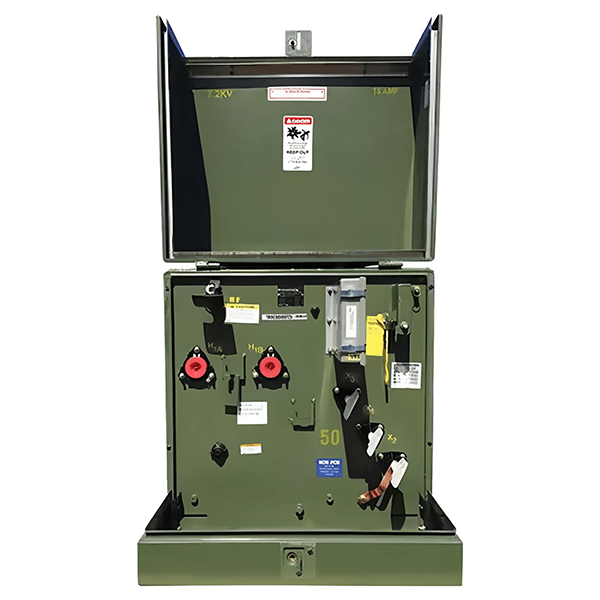

Transformateur monophasé de type poste | Conception étanche à haute isolation | Solutions de distribution électrique personnalisées Hongye Electric

Disjoncteur sur colonne ZW20-12Z

Transformateurs Triphasés sur Socle de Style Américain | Solutions de Réseau Sûres et Efficaces

Laissez vos coordonnées et nous vous contacterons pendant les heures de bureau

Accueil >

Accueil >