Sản phẩm

Năng lượng mới, điện gió, điện quang điện.

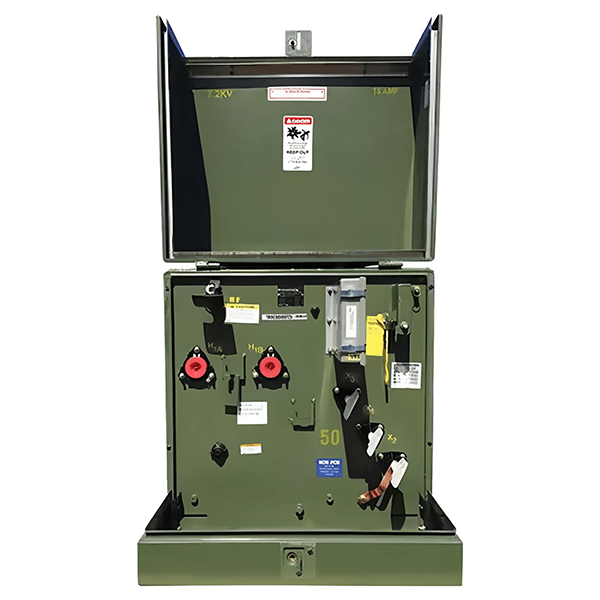

Ứng dụng sản phẩm: Máy biến áp hộp năng lượng mới là thiết bị phân phối điện tích hợp được thiết kế đặc biệt cho các tình huống năng lượng mới như phát điện quang điện, phát điện gió, hệ thống lưu trữ năng lượng, thông qua kết cấu tích hợp"kết nối cao áp - máy biến áp - phân phối điện hạ áp", giải quyết vấn đề khó khăn về kết nối"bên phát điện - bên lưới điện"của phát điện năng lượng mới, là một trong những thiết bị cốt lõi của trạm điện năng lượng mới, lưới điện siêu nhỏ và hệ thống năng

Thiết kế cốt lõi và đặc tính kỹ thuật: Biến đổi hộp năng lượng mới tập trung vào nhu cầu"độ thẩm thấu cao, biến động và môi trường ngoài trời"của sản xuất điện năng lượng mới, với lợi thế cốt lõi là"khả năng thích ứng mạnh, an toàn và đáng tin cậy, thông minh và hiệu quả cao".

Kết cấu tích hợp, triển khai hiệu quả: áp dụng thiết kế mô - đun ba khoang"buồng áp suất cao + buồng biến áp + buồng áp suất thấp", tất cả thiết bị tích hợp trong hộp kín, nhà máy đúc sẵn hoàn thành điều chỉnh thử, hiện trường chỉ cần thi công cơ sở và kết nối, thời gian thi công rút ngắn 70% so với phương án truyền thống, đặc biệt thích hợp với các trạm năng lượng mới có điều kiện thi công phức tạp như vùng sâu vùng xa, vùng núi, sa mạc.

Các thông số điện:

Đẳng cấp điện áp: bên cao áp hỗ trợ 10kV/35kV (dòng chính) hoặc tùy chỉnh (như cảnh điện gió ngoài khơi 66kV); bên thấp áp 0.4kV/0.69kV (thích hợp với đầu ra biến tần hoặc hệ thống lưu trữ năng lượng)

Phạm vi công suất: 50kVA~2500kVA (tiêu chuẩn), có thể mở rộng đến 5000kVA (dự án quang điện/điện gió lớn)

Khả năng chống nhiễu mạnh: nhằm vào đặc tính sóng hài và dao động điện áp của phát điện năng lượng mới, tối ưu hóa thiết kế cuộn dây (ví dụ như sử dụng lõi sắt hợp kim phi tinh để giảm tổn thất không tải), ức chế tỷ lệ biến dạng sóng hài (≤ 3%), đảm bảo ổn định điện áp nối lưới

Khả năng thích ứng với môi trường và bảo vệ nổi bật:

Cấp độ bảo vệ: Thân hộp được làm bằng thép không gỉ hoặc hợp kim nhôm, cấp độ bảo vệ đạt IP54 (có thể nâng cấp lên IP65), chống bụi, chống thấm nước, chống sương muối, thích ứng với môi trường khắc nghiệt như cao nguyên (≤ 4000m), ven biển (sương muối), sa mạc (nhiệt độ cao).

Thiết kế tản nhiệt: Bộ tản nhiệt tuần hoàn dầu tự nhiên tiêu chuẩn (ONAN) hoặc thiết bị làm mát bằng không khí tùy chọn (ONAF), đối phó với nhiệt độ cực đại -40 ℃~+ 50 ℃, đảm bảo hoạt động ổn định dưới tải trọng đầy đủ.

Kịch bản ứng dụng điển hình:

Nhà máy điện quang điện: kết nối biến tần chuỗi quang điện với trạm tăng áp, thực hiện kết nối lưới điện cao áp sau khi lưu chuyển trực tiếp;

Trang trại điện gió: Thích ứng với máy biến áp hộp trong tháp quạt (ví dụ như máy biến áp hộp đường dây thu 35kV), thu điện năng đến trạm tăng áp;

Hệ thống lưu trữ năng lượng: Là giao diện giữa bộ chuyển đổi lưu trữ năng lượng (PCS) và lưới điện, thực hiện biến áp hai chiều"sạc và xả";

HONGYE

HONGYE được đánh giá cao về khả năng xuất sắc trong việc thiết kế và giao máy biến áp hàng đầu. Chúng tôi có vị trí cao trong ngành, đồng nghĩa với chất lượng và sáng tạo. HONGYE có hơn 20 năm kinh nghiệm trong lĩnh vực máy biến áp, phục vụ các nhà sản xuất tại 26 quốc gia trên thế giới. Liên minh mạnh mẽ của chúng tôi với các nhà sản xuất máy biến áp hàng đầu và một đội ngũ hơn 200 chuyên gia sản xuất lành nghề và 56 chuyên gia trước và sau bán hàng tận tâm đảm bảo cung cấp cho khách hàng các giải pháp mua sắm toàn diện và liền mạch.

Ý tưởng công ty HONGYE

Kiểm soát chất lượng: Chúng tôi tuân thủ nghiêm ngặt các quy trình kiểm soát chất lượng từ sản xuất nguyên vật liệu đến mua sắm, đảm bảo máy biến áp của chúng tôi luôn tuân thủ và vượt qua các tiêu chuẩn và thông số kỹ thuật liên quan, đảm bảo tính năng và độ tin cậy không gì sánh kịp.

Dịch vụ khách hàng: Chúng tôi cam kết không ngừng nâng cao chất lượng và hiệu quả dịch vụ của mình, mỗi lần đều đáp ứng và vượt qua kỳ vọng của khách hàng với dịch vụ xuất sắc và nhất quán.

Gia công theo yêu cầu: Chúng tôi cung cấp các giải pháp máy biến áp được thiết kế riêng, được thiết kế tỉ mỉ để đáp ứng các thông số kỹ thuật và yêu cầu độc đáo của bạn, đảm bảo rằng mỗi ứng dụng đều phù hợp hoàn hảo.

Máy biến áp tiết kiệm năng lượng hiệu suất cao dòng S | Lõi thép ghép bậc thang & Công nghệ điều chỉnh điện áp dưới tải | Giải pháp phân phối điện ổn định

Máy biến áp treo cột một pha - Lõi hình xuyến, tản nhiệt hiệu suất cao, máy biến áp lắp cột độ ồn thấp

Nhà sản xuất máy biến áp khô đúc bằng nhựa epoxy | Máy biến áp khô hiệu suất cao, tiết kiệm năng lượng, chống cháy nổ

Máy biến áp đặt trên bệ một pha | Thiết kế cách điện cao, chống rò rỉ | Giải pháp phân phối điện tùy chỉnh Hongye Electric

Bộ ngắt mạch trên cột ZW20-12z

Máy biến áp ba pha kiểu Mỹ lắp trên bệ | Giải pháp lưới điện an toàn và hiệu quả

Để lại thông tin liên hệ và chúng tôi sẽ liên hệ với bạn trong giờ làm việc

Trang chủ >

Trang chủ >